Fully Automatic Weighing Systems

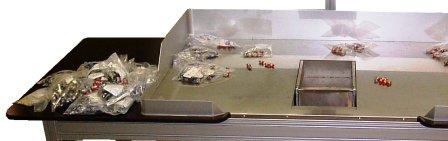

The use of vibratory conveyors (vibrating feeders) for the purpose of separating bulk materials reaches its limits as soon a very large product throughput is required. This is why larger quantities are split using automatic scales. In this case, the desired K K 339product quantity is calculated based on the overall weight, and separated into the target weight using vibration chutes. The result is that a huge amount of separated products can be packed straight into bags using the connected packing machine. If smaller batches need to be separated, and the investment is too high for fully automatic scales, there is also the option of using table-top scales as a semi-automatic batching solution. tischwaageals Using this method, the products are placed on a work table before the operator lays them on the weighing tray in batches. The operator can see the amount of products that has been placed on the scales online on the machine display panel, and then quickly alter the quantity if necessary.imageThe table-top scales either come with a static weighing bowl (for small quantities) or with an automatic tipping device (standard).